On a recent ride one of the screws holding the tachometer face on vibrated out. You can see it down by the high beam light. It seems rather common on these old bikes, so here's how I fixed it.

Remove the headlight lens to access the two tach connections, and pull the harness out of the back of the headlight. Unscrew the tach cable from the back of the tach, and remove the two lower 10mm nuts.

Remove the two 8mm nuts on the side and pull the tach out of the shell.

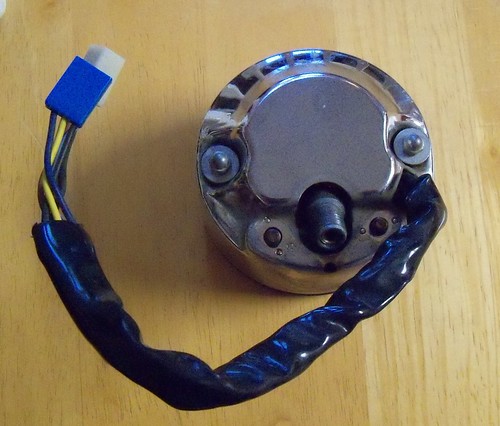

The tachs are sealed, so I decided to cut it open to fix it, using a coping saw. It cuts through the plastic easily, and makes it easy to keep from cutting too deep into the tach. I first marked a line perpendicular to the cut to help line it back up once ready to reassemble.

Here it is cut open. I've heard of people prying the metal bezel off, but this seemed like a better way to do it. I don't know if I could have done it without causing visible damage.

Here's the top, and one area you need to be careful not to go too deep when cutting...

...and also on the bottom. If you need to get inside the tach to fix something, remove the two screw next to the cable drive and the whole thing will pull out. You can see one of the marks I put to line it back up.

The screw back in, and ready to reassemble. I used just a tiny drop of blue Loctite on the screw. Be sure to carefully blow out any plastic shavings from the cutting before reassembly.

Back together here. Lots of ways to do it, but I used a good 3M electrical tape rather than gluing it back together, in case I ever need to take it apart again.

Now it's ready to stick back in the shell, and put back on the bike.