I used a die grinder with a carbide bit to fit the tail light to the bum stop.

The exhaust that I picked up earlier this year at a swap meet didn't use a center mounting point like the stock system, so I made some brackets that connect the muffler clamps to the center stand tabs, just to strengthen it up a bit.

To attach the fiber glass seat pan to the steel base I drilled some sheet metal and welded in bolts. The sheet metal is to keep the bolts from turning when tightening or loosening. I drilled the pan for aluminum pop rivets to fasten the upholstery, in case I decide to have it wrap under the pan.

The fasteners in place. If I decide to have the upholstery snap to the sides of the seat base, which is what I'm likely going to do, these aren't needed, but won't hurt anything being there.

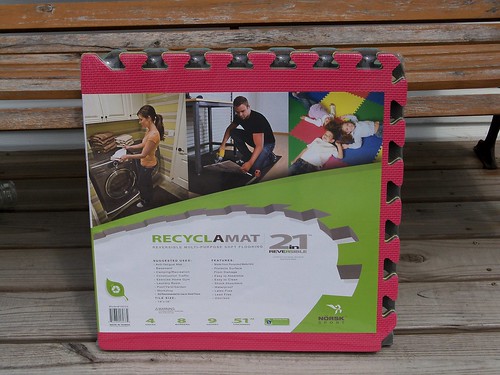

For the foam I'm using the same stuff from Menards as I did on the SR500 seat. Most any firm closed cell foam will work great, like exercise mats and things like that. They hold there shape nicely, don't soak up moisture, and don't need much thickness for comfort.

I used a hot glue gun to attach it to the pan. Since it sets up in just a few minutes, I did small sections taping it as I went.

I did two layers of the foam, and then started trimming.

For the rough trimming, an angle grinder with a cutoff wheel works great, and with a flap wheel for rough shaping. For final shaping and smoothing a wood rasp and inline sander work nicely.

It is ready for tear down. I'm going to do the chassis and body related work this summer and fall, which will be the easiest part. That will be sand blasting and painting the frame and related parts, and painting the body pieces. It will get tapered steering bearings and bronze swingarm bushings. The engine and wheels I'll do this winter, since I can do them in my basement shop. The engine and wheels will involve lots of aluminum polishing. I know the engine needs new cam chain guides, so will get those and a new cam chain. I'll have to see what the rest looks like when it gets opened up. The wheel rims and hubs will be polished and I'll lace them with stainless steel spokes.

No comments:

Post a Comment