I would have left the sticker if it was in better shape.

To keep the damper tube from spinning when loosening the bottom bolt, you can make a tool to fit the top. It has flats on the sides, and you can grind 4 sides from a 12mm 6 point socket to fit.

You can also leave the springs in the forks to put pressure on the tube, and remove the bolts with an impact gun.

Old fork seals can really be stuck in place, but some heat usually makes them come out with little effort. I use a propane torch, and while holding the slider about half way down and turning it to heat it evenly, as soon as I can feel it getting warm I'll try to remove the seal.

To clean the sliders I first used Rust-Oleum aircraft stripper to remove the clear coat. I then used a scotch-brite pad and soapy water to clean off the oxidation that forms under the clear. Then wet sanding with soapy water first with 800 grit and then 1000, and finally rub them out with Autosol polish.

Here are the other parts cleaned and ready for reassembly.

I'm using All Balls fork seals part # 55-109. The new dust wipers are from The Vintage Spoke. They look very nice and fit perfectly.

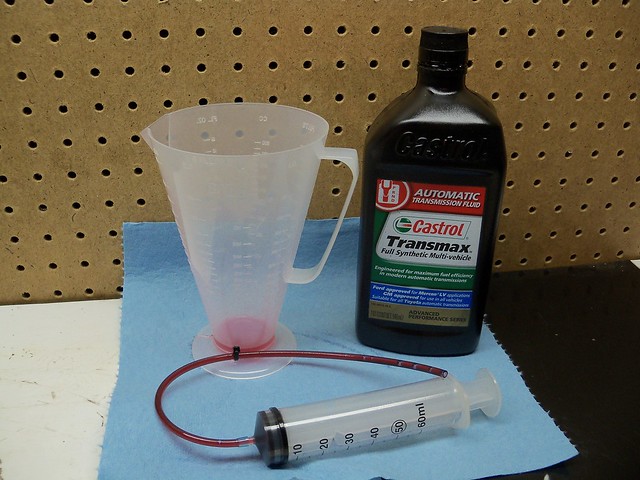

I'm using the same Castrol synthetic ATF as I used in the rear shocks. I wasn't sure where to start on oil level, but you have to start somewhere and tune from there once the bike is riding. I put 225cc in each leg, and then added just a little more to bring the level to 6 inches from the top with the forks collapsed and the spring removed.

Here they are ready to go.

Those turned out great! Very timely, I am about to rebuild some XS650 forks and get them all cleaned up to put on my XT.

ReplyDelete