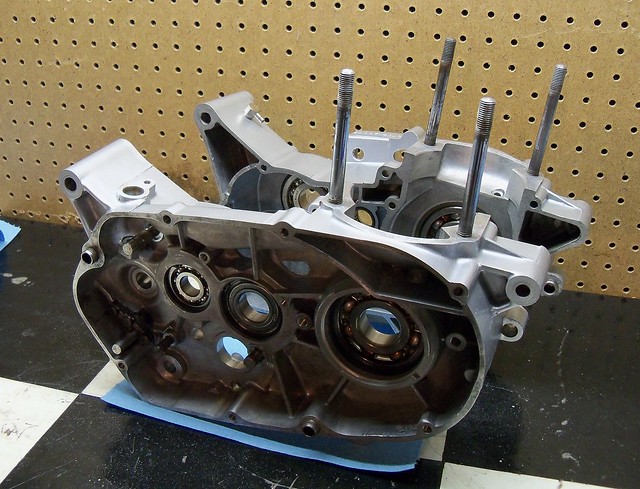

Here the six case bearings are installed. After this I put the case halves together and measured the main bearing width on the inside, and measured the crankshaft width at the bearing contact area. There is a shim that goes on the right side of the crankshaft that needs to be roughly half the difference of the two measurements to center it. The shim that came out of the engine was just right with the new bearings.

The transmission was in excellent shape, just needing to be disassembled and cleaned.

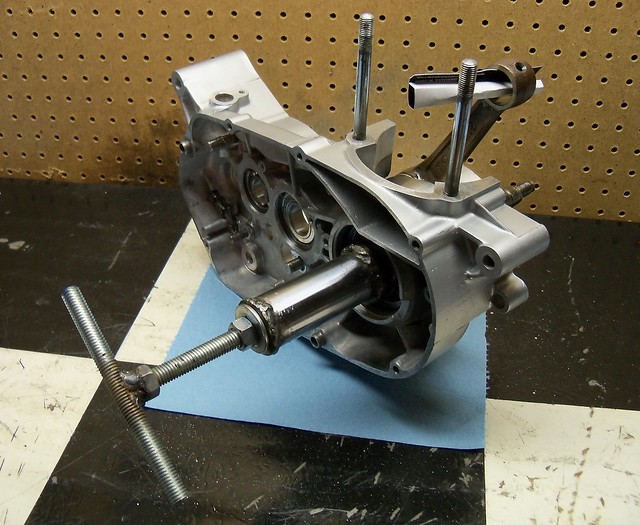

Here the crankshaft is being pulled into the right side main bearing.

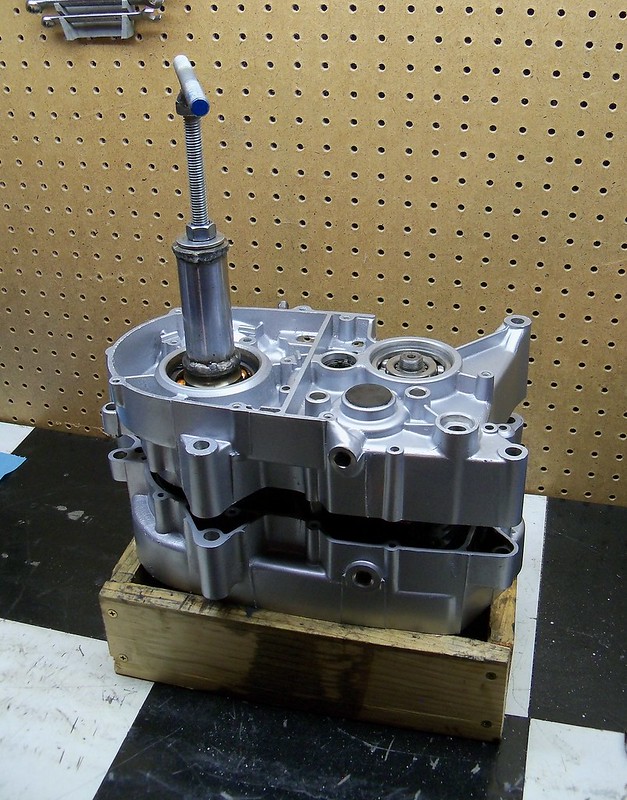

Then the transmission goes in. After this the case mating surfaces are cleaned and sealer is applied using a small modelers paint brush.

Here the left side case is going on by pulling the crankshaft into the left side main bearing, making sure the transmission shafts line up.

The cases are back together.

nice!

ReplyDelete