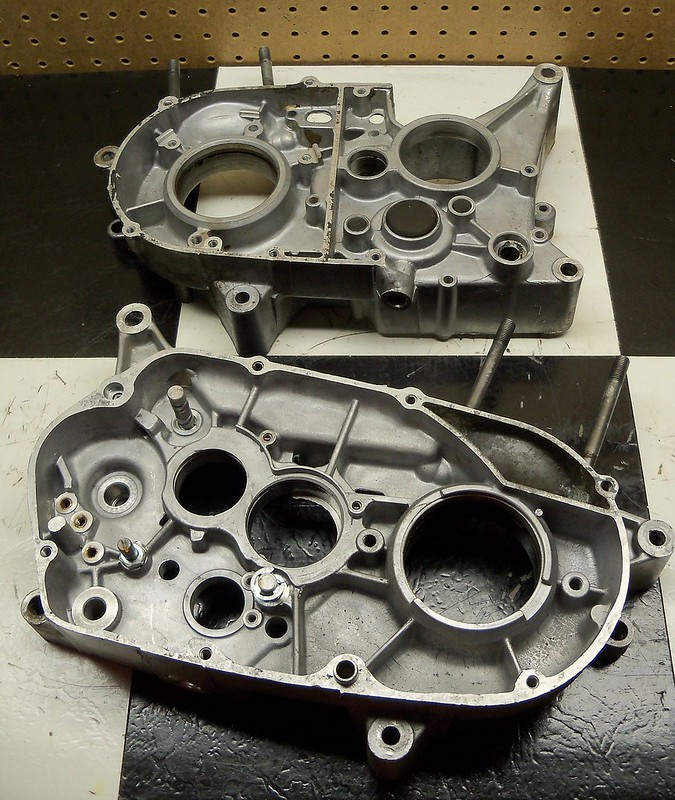

You'll see a lot of casting flash that can appear to some to be cracks at a quick glance. These are normal.

This angle shows it better. If doing a concours type restoration you want to leave these, but I'll be sanding most of it off.

One of the best tools in the shop is the digital camera, so take lots of pictures. You never know what might come in handy later on during assembly.

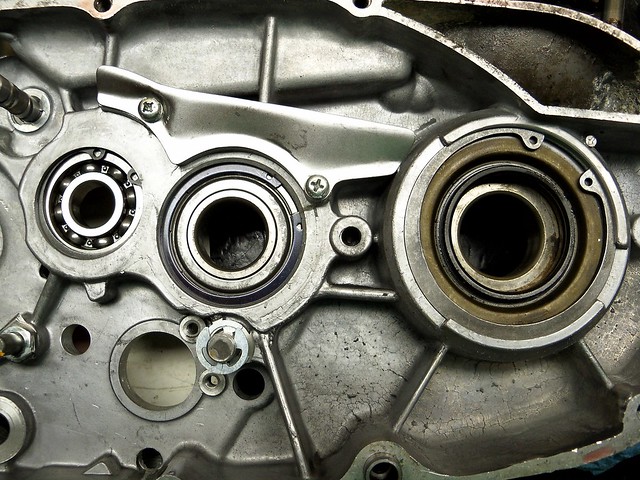

Many of the circlips need to be positioned a certain way or they will block oil passages, so take note of those.

To remove the bearings I first gave the cases a quick wash to remove any oils. I then got out the sockets I'll need to drive out the bearings. I heated them to about 200 degrees F. I then lay the cases on some plywood to protect the mating surfaces, with any dowels hanging off the edge so the cases don't warp, and drove out the bearings.

I save the old bearings so I can measure and compare them with the new ones.

Now I need to do the final cleaning and detailing on the cases, and they will be ready for the new bearings.

No comments:

Post a Comment