I'm using a complete seal kit from

Rusty Riders.

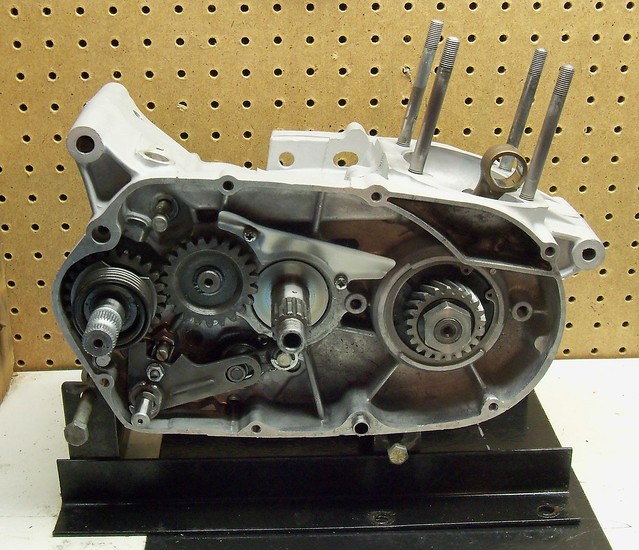

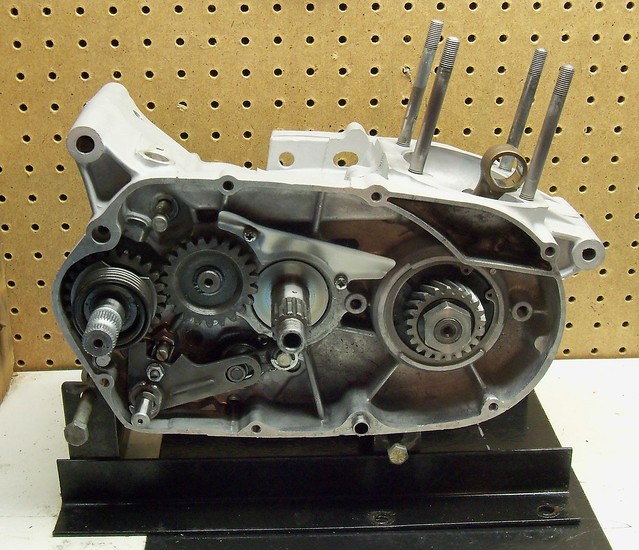

Here is the kick start assembly cleaned and ready to reassemble.

An example of things to look for when reassembling parts, there is a mark on the ratchet wheel that needs to line up with a mark on the kick axle so that the torsion spring has the correct tension.

Here it is assembled.

After the clutch is back on and the covers polished, the bottom end will be done.

The cylinder I'm using is at the 1st oversize (70.25mm), but has some scoring and will need to go at least one more oversize. Before boring I'm going to do some mild porting, so wanted to get it cleaned up first. I bead blasted it.

One of the best ways to loosen carbon buildup is to use paint stripper.

It melts most of it away, and a brass brush helps get the tougher carbon.

I then pressure washed it to remove the paint stripper and any left over blasting media, and brushed ATF on the iron parts to prevent flash rusting. Here you can see some of the cylinder wall scoring.

For the port work I'm just going to smooth and blend some of the rough areas of the castings, like in the exhaust port shown here. Once that is done I'll take it to the machine shop and see what oversize it will need.