I'm getting fairly close to starting up the '75 and see if it runs (or if I screwed anything up!). Lots of little things to do like replacing the alternator brushes, one of the old ones here with the new one.

For ignition I'm using the stock dual points with a single dual lead coil,

MikesXS part #17-6822. Both points get wired together with a single condenser. This is called a "wasted spark" system since both plugs fire at the same time. This coil has likely triple the voltage of the stock coils.

I made two aluminum brackets that mount the coil sideways using the front two stock coil mounting points.

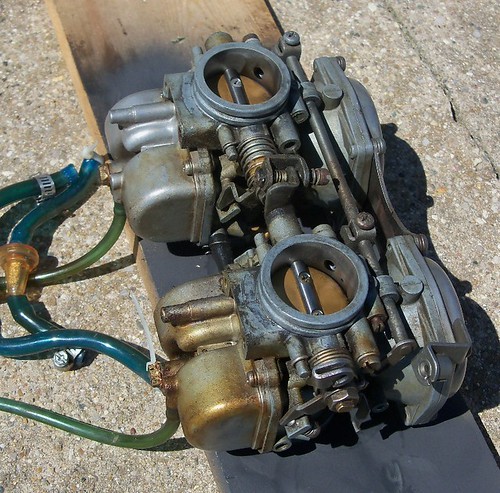

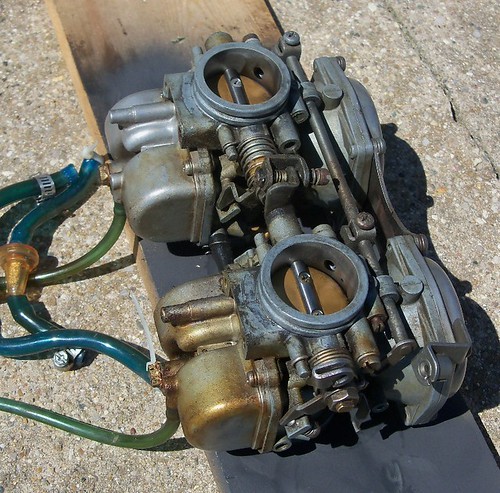

1975 had unlinked BS38 carbs using two throttle cables. When I bought mine it had a linked set using one cable, so I knew they had been swapped at some point. Before ordering parts I needed to identify what year they were. They turned out to be '76-'77 carbs, which use some different parts than the '78-'79. They were in decent shape but missing the choke lever and the lower link bar. The link bar is just steel angle stock, so I made one to fit.

Some new parts from MikesXS, rebuild kits, drain plugs, Z-8 needle jets and o-rings, and the choke lever. My carbs had the stock '76-'77 25 pilot and 122.5 main jets, so I went up two sizes on each to a 30 pilot and 127.5 main, which should get me close enough to start with.

The slide diaphragms looked crusty.

I bought new diaphragms from

JBM Industries. These are excellent quality, and a

huge money saver compared to what replacement slides cost. It use to be people would junk a set of carbs with bad diaphragms since they were so expensive, which is likely what happened to the originals on my '75.

First cut the old plastic retaining washers off, and clean the slides. On the JBM website they show snips being used to cut the rings, but I did it a different way since my cutters just wanted to slip off. I first cut as far as I could with a small cut-off wheel, stopping before getting to the slide. I then used a sharp utility knife, just using a rocking action to cut the small remaining part.

The diaphragms are a very snug fit on the slide, but I did use one drop off super glue to prevent the slides from rotating, as the website says it doesn't hurt to do so.

Ready to go back on the bike.

I bought a Uni filter kit part #PK-82. These are 3" long, but 4" would have cleared the battery box.

The stock carb holders were ready for retirement.

The new replacements are also from

JBM Industries. Like the diaphragms they are designed to withstand ethanol blend fuels, and also made to be used with unsupported carbs when not using the stock airbox.

They use automotive hose clamps, which I covered in heat shrink to make less visible.

The '75 cam chain tensioner is huge compared to later models like my '79, so unscrewing it makes installing the carbs much easier.