12/31/14

12/30/14

12/29/14

DT1 MX project

I bought a set of Pirelli MT16 tires for the DT1 project. OldMotoDude put a set on his Pursang earlier this year, and they looked just right. They get great reviews, and aren't too expensive. They were $69.95 each with free shipping from Bike Bandit.

I got a 110/100-18 for the rear and 80/100-21 front.

The rear mounted on a 2.15" rim measures about 4"(101 mm) wide at the sidewall and 4.75"(121 mm) wide at the knobs.

I got a 110/100-18 for the rear and 80/100-21 front.

The rear mounted on a 2.15" rim measures about 4"(101 mm) wide at the sidewall and 4.75"(121 mm) wide at the knobs.

12/28/14

12/25/14

12/21/14

12/20/14

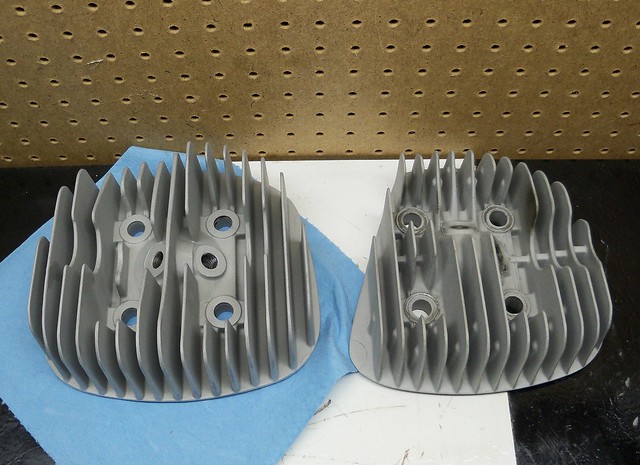

DT1 MX project

I'm using a used welded crank that measured to be in very good shape. The shim is for the right side of the crank.

First the cases are dry fit, and the distance between the main bearings measured. The crank width at the bearings and the shim are also measured. The difference between the crank and bearings should be roughly twice the measurement of the shim. The crank is installed in the right case with the shim in place, and fully seated against the bearing. This makes sure the crankshaft is centered.

Here the crank and transmission are put in the right side case, I next used a small brush to paint on a thin coat of ThreeBond 1194.

I then used my crank installation tool to install the left side case. The left side of the crank "floats" in the bearing, so stop once the cases are seated. I then used stainless cap screws with anti-seize to fasten them together.

Here it is on the stand.

First the cases are dry fit, and the distance between the main bearings measured. The crank width at the bearings and the shim are also measured. The difference between the crank and bearings should be roughly twice the measurement of the shim. The crank is installed in the right case with the shim in place, and fully seated against the bearing. This makes sure the crankshaft is centered.

Here the crank and transmission are put in the right side case, I next used a small brush to paint on a thin coat of ThreeBond 1194.

I then used my crank installation tool to install the left side case. The left side of the crank "floats" in the bearing, so stop once the cases are seated. I then used stainless cap screws with anti-seize to fasten them together.

Here it is on the stand.

12/16/14

12/15/14

DT1

12/13/14

DT1 MX project

I got the six engine case bearings, buying them all on ebay. These should be the same for all the '68-'73 DT and RT engines. The main crank bearings are Yamaha part number 93306-30630-00 and are no longer available, so I bought two Nachi 6306 open C3 bearings.

The smaller left side transmission bearing is Yamaha part number 93315-22004-00, and the bigger one is 93306-30506-00. Both are still available from Yamaha, and I went with OEM on these.

The smaller right side transmission bearing is Yamaha part number 93306-20306-00 and is still available, so I got an OEM bearing for this. The single shield larger right side transmission bearing is Yamaha part number 93306-20503-00, and it is no longer available, so I bought an NSK 6205ZC3. For all six bearings it came to about $107 shipped.

I put the bearings in the freezer ahead of time, and all but one of the circlips goes in the cases first. I warmed the cases in the oven to 200 degrees F. It seems like the bigger the bearing the more likely it will just drop right in, and the smaller ones need a little help. I have sockets ready to help drive them in if needed. Be sure to clean the sockets first, especially the inside, since you don't want any grit to fall on the bearings.

I'll be getting ready to assemble the bottom end of the engine.

The smaller left side transmission bearing is Yamaha part number 93315-22004-00, and the bigger one is 93306-30506-00. Both are still available from Yamaha, and I went with OEM on these.

The smaller right side transmission bearing is Yamaha part number 93306-20306-00 and is still available, so I got an OEM bearing for this. The single shield larger right side transmission bearing is Yamaha part number 93306-20503-00, and it is no longer available, so I bought an NSK 6205ZC3. For all six bearings it came to about $107 shipped.

I put the bearings in the freezer ahead of time, and all but one of the circlips goes in the cases first. I warmed the cases in the oven to 200 degrees F. It seems like the bigger the bearing the more likely it will just drop right in, and the smaller ones need a little help. I have sockets ready to help drive them in if needed. Be sure to clean the sockets first, especially the inside, since you don't want any grit to fall on the bearings.

I'll be getting ready to assemble the bottom end of the engine.

Subscribe to:

Comments (Atom)